I have been planning this for a while so now it is time to try. The use of Oak is praised on pretty much every page talking about oak and mead so I have to try it out too.

I purchased 250 g of American Oak chips which should give taste quickly, though less complex. Other options would be French or Eastern European oak. French should give a more complex Oak taste but should also be able to over power a mead quickly. Eastern European oak should release taste slower and the taste should be much less intense. With absolutely no experience with oaking mead I figured the American oak chips would be the best chips to start with :o).

Furthermore the oak can be toasted to several levels. The main types used are light toast, medium toast and heavy toast, each imparting different taste notes. Apparently medium toast is by far the most recommended to start with. so American oak chips - medium toast it is :o)

I have also been looking for a guide for dosing the oak. The best I could find was actually from where I bought the chips (Dansk Hjemmeproduktion). Here the recommendations are:

White wine: 50-150g / 100L

Red wine: 100-250 g / 100L

Extraction time: 4-12 weeks.

Again I figured I would start somewhere in the middle - something that would go for both red and white wine, i.e 125 g / 100 L or 25g / 20 L.

Just found another reference HERE from E.C.Kraus. This is by far the best web page I found so far regarding oaking. And as a bonus there is a bit about the history of oaking.

So here we go:

The chips I bought contains lots of little bits that will be able to go through the "hop bag" that I will use for the chips. The get rid of these I just used my spaghetti strainer with a plastic bag underneath.

In this way I lost about 45 g of the 250 g bag that I bought. But now, at least, most of the chips should stay in the hop bag. This is definitely one good reason to use oak cubes next time if available.

I weighed out 25 g in a hop bag, and tied the bag up at the opposite end, so that the chips would not be pressed together in a small space - more free and available surface, better extraction.

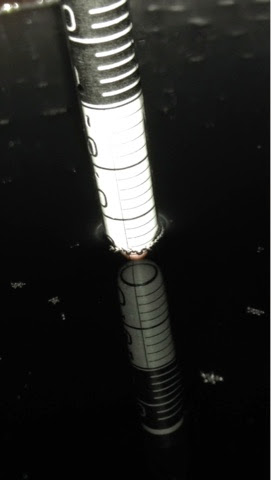

Then I boiled the bag shortly. The water quickly got colored, and I became unsure whether this was the taste components I wanted in my mead, so I just boiled for 10 sec or so. I am not so worried about contamination since the mead has finished fermenting with a high content of ethanol (14-15%). This should be too harsh for most wild yeast.

Also in the picture below I took a sample of the mead for tasting, so that I can compare "before" and "after" oaking.

Finally I drained the pot for water and left the hop bag in the pot to cool for a few minutes. Hereafter I just dropped the hop bag into the currant mead, and closed the lid.

Now I will just have to wait. I will test the the mead weekly to see how it develops.

I read that the chips will sink once they get fully soaked. Come to think of it, I should perhaps have tied a string to the bag which I could have attached to the edge of the fermenter. In this way I would not have to "spoon" the bag out later. Fingers crossed that it will not be that difficult and that the sediment will quickly settle again.

This is a blog about the joy of brewing mead and acquiring the honey, fruits and spices that are used for each batch of mead. I'm a bee keeper in my spare time and the fruits/berries and spices are preferably from my own garden or gardens nearby.

Sunday, 23 November 2014

Thursday, 20 November 2014

2014 batch 2: Currant mead (8) - Check

After finishing up with the cyser I just did a check on the currant mead.

Oe: 26 (OK)

pH 3.45 (Uh, somewhat lower than I wanted)

The color is great - bright red - and not pink that I was initially afraid of since the amount of juice was quite limited. It has also cleared quite well already.

I need to lift pH a bit which I will do with potassium carbonate. I just need to test how much to add.

Finally I covered the mead with a layer of CO2 (See "CO2 generator" under Knowledge Tools), sealed the lid, and attached the airlock.

Oe: 26 (OK)

pH 3.45 (Uh, somewhat lower than I wanted)

The color is great - bright red - and not pink that I was initially afraid of since the amount of juice was quite limited. It has also cleared quite well already.

I need to lift pH a bit which I will do with potassium carbonate. I just need to test how much to add.

Finally I covered the mead with a layer of CO2 (See "CO2 generator" under Knowledge Tools), sealed the lid, and attached the airlock.

2014 batch 1: Cyser (7) - Back sweetening

Time to back sweeten the cyser. Opening the cyser it is almost clear and the milky smell is not pronounced in any way any more. The current Oechsle value is now 18. Last time I measured it, the values was 16 so I assume that the high level of dissolved CO2 interfered with the measurement. The taste is nice - like sherry -but it does need just a little bit more sweetness, so I decided to add honey to 25 degree Oe. Using the same scheme as for the currant mead I get:

The procedure is the same: 470 g of honey in a clean bowl. About 1.5 L of cyser, stir for quite a while (but not vigorously) to dissolve the honey and and pour the solution back into the fermenter. Rinse the bowl with another 1 L of cyser. Then give the fermenter a quick stir and attach the lid and airlock

The next day I checked the mead after it had been settling:

Oe: 25

pH: 3.64 (a little low)

Almost Perfect :o)

Since it is not fermenting any more, I want to cover the mead with a layer of CO2 to avoid oxidation. For this I used my trusted CO2 generator. You can find directions for the generator in Knowledge Tools in top right corner of this blog.

My plan was initially to the honey that was left for this batch since I only used 4.8 kg of the 7.2 in stock. But I used it all for back sweetening my currant mead (first to lift the Oe after addition of juice and the rest for back sweetening). Instead I will use the late summer honey. It is quite fragrant compared to the summer initially used for this batch. Hopefully it will give more honey odor initially before the sherry like taste sets in. .... and mask any residual yogurt like smell from the malolactic fermentation.

The procedure is the same: 470 g of honey in a clean bowl. About 1.5 L of cyser, stir for quite a while (but not vigorously) to dissolve the honey and and pour the solution back into the fermenter. Rinse the bowl with another 1 L of cyser. Then give the fermenter a quick stir and attach the lid and airlock

The next day I checked the mead after it had been settling:

Oe: 25

pH: 3.64 (a little low)

Almost Perfect :o)

Since it is not fermenting any more, I want to cover the mead with a layer of CO2 to avoid oxidation. For this I used my trusted CO2 generator. You can find directions for the generator in Knowledge Tools in top right corner of this blog.

Sunday, 16 November 2014

2014 batch 2: Currant mead (7) - Racking

When I did the back sweetening I noticed that a layer of solids up to the 5 L mark of the fermenter. When I poured in the currant juice there was plenty of solids in there (cellulose?) which I also observed shortly after juicing the berries. I figure the yeast would break these solids down during the fermentation. This did apparently not happen :o( Also, I did not see a the thick layer of yeast at the bottom even though the top liquid had cleared. I guess that the yeast adhered to the solids to make a fluffy bottom layer that just did not sink below the 5 L mark.

So, today I tried to rack the mead. First I racked the top layer the normal way and put this aside. Looking into the fermenter I got a bit discouraged, but decided to give it a shot.

First I put a large coffee filter in a sieve and tried to filter the mead through this. Did not work. The liquid stop dripping shortly after I filled the filter.

Next step was to use a diaper cloth, which I rinsed on boiling water to ensure that it was clean. I put it in the sieve without folding it, and filled the sieve again. This time the liquid came through, but after a short time, the flow through the cloth was also blocked.

In the end, and after a lot of patience, I stopped. I poured the 1 L I did salvage into the new fermenter too, and the total volume was now only about 20 L.

The last 4.5 L was then poured............ in the toilet. !"¤%&¤#"?.

Now here is another lesson learned: Rack first, back sweeten afterwards!!!!!! And to step in it a little more: 4.5 L, or about 20%, means that I wasted 20% of the honey I back sweetened with - around 350 g down the drain.

So, today I tried to rack the mead. First I racked the top layer the normal way and put this aside. Looking into the fermenter I got a bit discouraged, but decided to give it a shot.

First I put a large coffee filter in a sieve and tried to filter the mead through this. Did not work. The liquid stop dripping shortly after I filled the filter.

Next step was to use a diaper cloth, which I rinsed on boiling water to ensure that it was clean. I put it in the sieve without folding it, and filled the sieve again. This time the liquid came through, but after a short time, the flow through the cloth was also blocked.

In the end, and after a lot of patience, I stopped. I poured the 1 L I did salvage into the new fermenter too, and the total volume was now only about 20 L.

The last 4.5 L was then poured............ in the toilet. !"¤%&¤#"?.

Now here is another lesson learned: Rack first, back sweeten afterwards!!!!!! And to step in it a little more: 4.5 L, or about 20%, means that I wasted 20% of the honey I back sweetened with - around 350 g down the drain.

2014 batch 2: Currant mead (6) - Back sweetening

It seems like the fermentation is still going but at a very slow rate. I measured the gravity to just 1.002 so this is likely part of the reason. I am surprised that my Sweet Mead Yeast has pretty much used the entire amount of sugar - Sweet Mead my a.. :o).

Tasting the mead, it has plenty of acidity and a slight taste of red currant. The smell and flavor of the black currant is gone, but the color of the mead is fantastic - a strong light red color.

This is something to remember - use one third red currant for acidity and two thirds black currant to make up for color.

Due to the acidity I figured some sweetness from honey would be welcome, so I decided to target a final gravity of 1.025. Using the calculations in last post in a spreadsheet looks like this:

With a target Oechsle of 25 and a starting Oechsle of 2 in a total volume of 23.5L, I need 1713 g. In fact I had about 1775 g left from my cyser (calculated using the tara value of the container)

I poured what I could into a clean bowl and dissolved it in 1.5 L of the mead. This takes a loooooong time when the liquid is not heated. With some patience it slowly dissolves. Then I poured the content of the bowl back into the fermenter and rinsed the bowl repeatedly with the mead. Then I poured some mead into the honey container to rinse it too. Judging from the tara value I had gotten about 1760 g out. This corresponds to a new Oechsle of 26.

I left the fermenter overnight to fully dissolve the honey and measured the gravity the next day:

I read this as just slightly below 1.026, and well within expected uncertainties. The total volume is now 24.5 L so there will be mead enough for all.....

The equations work :o)

The equations work :o)

Tuesday, 11 November 2014

Back sweetening - The Honey-Oechsle equation

"Three is the magic number" as the saying goes, and that is right for honey too. I always use 7.2 kg of honey for 20L must because I know I will have a gravity of 1.120 or Oechsle value of 120 degrees. The ratio between Oechsle value and honey concentration, which I call the honey factor, is then equal to 0.3333, and hence the inverse of this factor is exactly 3.

Using this factor, it then becomes very easy to calculate how much honey to use to reach any target Oechsle value.

Now, this factor can also be used when adding fruit juice, by expressing all the sugar content of the juice as honey. This calculation also takes into account the additional volume. In the end the honey factor is eliminated. As the examples show, you can either calculate the new Oechsle value when adding a fixed volume of juice/extract, or you can calculate how much juice/extract you need to reach a target Oechsle value.

Finally you can use the same set-up for calculating how much honey to use for back sweetening. This time you will need the inverse honey factor and the density of the honey. I usually use the value 1.35 g/ml for the density which is used to calculate the volume increase. As before, examples illustrate how you can either calculate the new Oechsle value when adding a fixed mass of honey, or you can calculate how much honey you need to reach a target Oechsle value.

These calculations work great in Excel and they are a great help if you, for example, want to add honey to a target Oechsle value and be spot on first time :o)

Limitations

What are the limitations? The equations do not take into account that the gravity is lowered due to the content of alcohol. If all has been converted to ethanol, the density should not be lower than 0.970, i.e. a correction of 3% would be needed. But 3% is likely well within the error of all values going into the equations, and it would not improve your result significantly.

The inverse honey factor are of cause dependent on the water content of the honey. As a mead maker you will of cause be using high quality honey where the water content is only 15-17%, i.e. within a quite narrow range. Hence, this variation in sugar content will also be small.

The biggest contributor to error is, as I see it, the density of honey. I do not have data showing the variations in density in various honeys. Never the less, the density is used to calculate the added volume, and this volume will always be small compared to the volume of the must, i.e. a large error will not influence the new Oechsle value very much.

Mixing volumes might not be exactly equal to the sum of the individual volumes, but again the correction would be smaller than the error of other values.

Monday, 3 November 2014

2014 batch 1: Cyser (6) Adding yeast stopper

Sometimes in between kids dinner and diapers and bed time my head is just not screwed on right. When I did the racking of the cyser yesterday and even realized that the mead is almost to lactic, I forgot to add the sodium metabisulfite/potassium sorbate that should inhibit the malolactic bacteria. Even though the airlock is not bubbling regularly the process could still be ongoing at a slower rate, and I do not want any more lactic acid in the cyser if I can avoid it.

So today I added the sodium metabisulfite/potassium sorbate today and gave the fermenter a good stir, but no splashing. Thank god I remembered

Just as last year it comes in a prepacked mix that should be adequate for 20 L batches. The total mass of content should be 7 g. So another thing on the to do list is to figure out how much of each component there are in a package.

So today I added the sodium metabisulfite/potassium sorbate today and gave the fermenter a good stir, but no splashing. Thank god I remembered

Just as last year it comes in a prepacked mix that should be adequate for 20 L batches. The total mass of content should be 7 g. So another thing on the to do list is to figure out how much of each component there are in a package.

Sunday, 2 November 2014

2014 batch 1: Cyser (5) Racking and sampling

Also racked the Cyser today. It has stopped bubbling and the water in the airlock has leveled out. The data was

SG: 1.016

pH: 3.68

Temp: 24.7 C

I took another sample for the TLC analysis that I have not yet had time to set up .... it will soon be on the top of the "to do list"

The transformation of the taste is quite significant. The stinging acidic taste of the malic acid is completely gone and the mead now has a slight yogurt like taste to it which will hopefully not become any more pronounced. It is quite pleasant to drink but I think back sweetening with honey to SG 1.020 - 1.025 will do wonders.

SG: 1.016

pH: 3.68

Temp: 24.7 C

I took another sample for the TLC analysis that I have not yet had time to set up .... it will soon be on the top of the "to do list"

The transformation of the taste is quite significant. The stinging acidic taste of the malic acid is completely gone and the mead now has a slight yogurt like taste to it which will hopefully not become any more pronounced. It is quite pleasant to drink but I think back sweetening with honey to SG 1.020 - 1.025 will do wonders.

2014 batch 2: Currant mead (5) - Addition of currant juice

In the afternoon Saturday the 1st of November I took out the currant juice from the freezer. The juice was prepared this summer as described HERE. It is the steamed juice of red currant and black currant from the ribes bushes in our garden. The volume is about 3.5 L and consist of approximately 1.25 L of red currant juice, and 2.25 L of black currant juice

Sunday the 2nd of November

In the morning I checked that the juice had thawed and the temperature was just below room temperature. I emptied the juice into a clean fermenter and then I just racked the batch onto it, stirred a bit, and closed it up. After the addition SG was 1.011 so there was plenty of sugar in. Secondly the total volume is now 23 L, so assuming that I was at about 15% ABV at the time of racking, I am now at 13%. Further more, if 1% ABV is generated from a gravity change of 0.00753, then the mead can potentially convert a gravity of 1.015 to 1.000, i.e. I am a bit short in sugar - 0.004 gravity units

So if 7.2 kg gives a gravity of 1.120 then I am 240 g of honey short. So I added 300g (actually 295g) which should add about 0.005 to the gravity.

About 5 hours later I measured gravity and pH again

SG: 1.011

pH: 3.41

Temp: 24.7 C

I noticed that pH dropped significantly when adding the juice - from 3.7 to 3.4. Also the mead is now foaming quite a bit so there was plenty of proteins in the juice also. I am not sure this was a good thing. If the fermentation stops completely, some not so pleasant compounds might be present due to partially degraded protein. Well, now I will just have to see if the fermentation will run for at least 24-48 hours more and then stop before the batch runs out of sugar :o).

______________

In all calculations I do not take into account that ethanol lowers the density of the solution. All measurements are with quite large uncertainty anyways, so adjusting for ethanol content by extensive calculations just seems like overkill.

2014 batch 2: Currant mead (4) - fermentation is ending after just week :o)

I continued to monitor the gravity, pH and temperature after the last addition. All measurement were done in the evening so that the intervals between measurements were as close to 24 hour as possible

Thursday the 30th of October

Sg: 1.040

pH: 3.69

Temp: 23.6 C

Friday the 31th of October

Sg: 1.022

pH: 3.68

Temp: N.A.

Saturday the 1st of November

Sg: 1.010

pH: 3.70

Temp: 22.7 C

So how does this SNA batch compare with the cyser. When plotting the gravity readings you get

Basically I had estimated that that a drop of 0.100 would correspond to 14 %. Hence if the yeast max out at 15%, it should not change gravity by more than 0.107 and should in this case have stopped at 1.013. Now it is 1.010 and it is still going strong even though the rate has been reduced a bit

The simple formula for calculating Alcohol by volume is:

ABV= (OG-FG)/0.00753 (ref wikipedia)

This basically says that the gravity changes by 0.00753, then 1% of alcohol is produced.

For high gravity there is a somewhat more complicated formula.

ABV =76.08*(OG-FG)/(1.775-OG)*FG/0.794

The idea is that more ethanol is produced at the end of the fermentation since the replication rate reduces. This means that more alcohol should be produces per gravity unit.

The high gravity formula (alternative formula) as it is returns ridiculously high ABV values - far higher than the yeast max, so I just adjusted the simple formula by using a factor of 0.0071. So 15%max x 0.0071 = 0.107.

Right now I am back to the original simple formula. Then, for an ABV of 15% the new low is 1.007 instead of 1.013.

Thursday the 30th of October

Sg: 1.040

pH: 3.69

Temp: 23.6 C

Friday the 31th of October

Sg: 1.022

pH: 3.68

Temp: N.A.

Saturday the 1st of November

Sg: 1.010

pH: 3.70

Temp: 22.7 C

So how does this SNA batch compare with the cyser. When plotting the gravity readings you get

I called it Sack as the currant juice has not been added yet, so as of now it is produced as a Sack mead. It is very clear what with Staggered Nutrition Addition you get a very fast and consistent fermentation (almost linear progress), which is at the end after 6-7 days :o)

Basically I had estimated that that a drop of 0.100 would correspond to 14 %. Hence if the yeast max out at 15%, it should not change gravity by more than 0.107 and should in this case have stopped at 1.013. Now it is 1.010 and it is still going strong even though the rate has been reduced a bit

The simple formula for calculating Alcohol by volume is:

ABV= (OG-FG)/0.00753 (ref wikipedia)

This basically says that the gravity changes by 0.00753, then 1% of alcohol is produced.

For high gravity there is a somewhat more complicated formula.

ABV =76.08*(OG-FG)/(1.775-OG)*FG/0.794

The idea is that more ethanol is produced at the end of the fermentation since the replication rate reduces. This means that more alcohol should be produces per gravity unit.

The high gravity formula (alternative formula) as it is returns ridiculously high ABV values - far higher than the yeast max, so I just adjusted the simple formula by using a factor of 0.0071. So 15%max x 0.0071 = 0.107.

Right now I am back to the original simple formula. Then, for an ABV of 15% the new low is 1.007 instead of 1.013.

Subscribe to:

Comments (Atom)