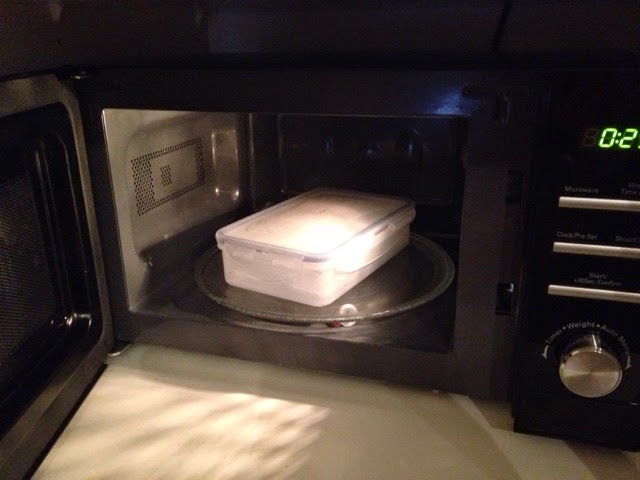

I added 25 g again, but this time I did not boil the oak. Instead I just rinsed the chips and hop bag in cold tap water and put the bag in the microwave for 60s at full power.

The smell of the wood was quite intense, and it must have been all that great stuff I boiled off last time. Then I took a small sample of the mead for reference before I finally I dropped the bag into the mead and sealed the fermentor.

Today, after 1½ week, I did a tasting and compared with the sample I took before the second oak addition. The fruitiness was still present but now the oak was quite significant but not overpowering the mead. So I decided to remove the oak again. Also, the mead feels sweeter with the oak, and the fruit acids had been mellowed out quite a bit. I get the feeling that when using oak I should probably not have sweetened the mead to 25 oechsle but rather stopped at 20.