I have been planning this for a while so now it is time to try. The use of Oak is praised on pretty much every page talking about oak and mead so I have to try it out too.

I purchased 250 g of American Oak chips which should give taste quickly, though less complex. Other options would be French or Eastern European oak. French should give a more complex Oak taste but should also be able to over power a mead quickly. Eastern European oak should release taste slower and the taste should be much less intense. With

absolutely no experience with oaking mead I figured the American oak chips would be the best chips to start with :o).

Furthermore the oak can be toasted to several levels. The main types used are light toast, medium toast and heavy toast, each imparting different taste notes. Apparently medium toast is by far the most recommended to start with. so

American oak chips - medium toast it is :o)

I have also been looking for a guide for dosing the oak. The best I could find was actually from where I bought the chips (

Dansk Hjemmeproduktion). Here the recommendations are:

White wine: 50-150g / 100L

Red wine: 100-250 g / 100L

Extraction time: 4-12 weeks.

Again I figured I would start somewhere in the middle - something that would go for both red and white wine, i.e 125 g / 100 L or 25g / 20 L.

Just found another reference

HERE from E.C.Kraus. This is by far the best web page I found so far regarding oaking. And as a bonus there is a bit about the history of oaking.

So here we go:

The chips I bought contains lots of little bits that will be able to go through the "hop bag" that I will use for the chips. The get rid of these I just used my spaghetti strainer with a plastic bag underneath.

In this way I lost about 45 g of the 250 g bag that I bought. But now, at least, most of the chips should stay in the hop bag. This is definitely one good reason to use oak cubes next time if available.

I weighed out 25 g in a hop bag, and tied the bag up at the opposite end, so that the chips would not be pressed together in a small space - more free and available surface, better extraction.

Then I boiled the bag shortly. The water quickly got colored, and I became unsure whether this was the taste components I wanted in my mead, so I just boiled for 10 sec or so. I am not so worried about contamination since the mead has finished fermenting with a high content of ethanol (14-15%). This should be too harsh for most wild yeast.

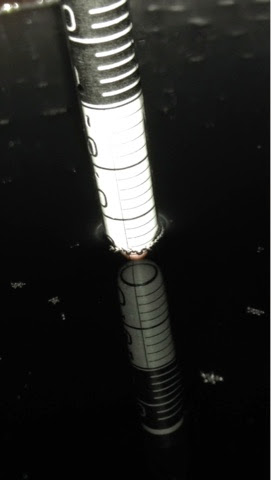

Also in the picture below I took a sample of the mead for tasting, so that I can compare "before" and "after" oaking.

Finally I drained the pot for water and left the hop bag in the pot to cool for a few minutes. Hereafter I just dropped the hop bag into the currant mead, and closed the lid.

Now I will just have to wait. I will test the the mead weekly to see how it develops.

I read that the chips will sink once they get fully soaked. Come to think of it, I should perhaps have tied a string to the bag which I could have attached to the edge of the fermenter. In this way I would not have to "spoon" the bag out later. Fingers crossed that it will not be that difficult and that the sediment will quickly settle again.